Understanding what winding tension is and its importance in web tension control may initially conjure up Newtonian laws of motion, which for some may sound intimidating or confusing. However, first consider the word tension by itself. With regard to physics, we learned in school that tension is one of many forces that exist in nature. As a force, how tension is transmitted is what distinguishes it from other forces such as compression or pushing, or thrust, weight, lift or drag. Tension, when applied, is a pulling force.

Like all forces in nature, it’s invisible and beyond the sense of touch, taste, and smell. Tension can be felt, though, literally and figuratively, for the word derives from the emotional state of being stretched or pulled. Being wound up is more than an expression; it is a form of tension. Apply that notion to physics and engineering, and it may be easier to grasp the concept of winding tension, but also its importance in relation to web tension controls that can improve production efficiency.

Winding Tension in Web Tension Control

In manufacturing, a web refers to any material that is continuously pulled on to a roll or reel, such as paper, plastic, film, filament, textile, cable or metal. Winding tension, as it applies to a continuous web of material in a machine process, is the single most important factor that ensures the web rolls evenly and processes properly. Meaning, the winding tension is the consistent, measurable force that the web needs to handle throughout the entire production process.

In manufacturing, a web refers to any material that is continuously pulled on to a roll or reel, such as paper, plastic, film, filament, textile, cable or metal. Winding tension, as it applies to a continuous web of material in a machine process, is the single most important factor that ensures the web rolls evenly and processes properly. Meaning, the winding tension is the consistent, measurable force that the web needs to handle throughout the entire production process.

When a material is wound through a machine, tension is the measurable force that elongates or stretches it as it is pulled, or transported, during the winding process. The amount that the material is stretched should be carefully controlled, and be kept to a minimum as well as evenly distributed throughout the entire process. Therefore, to control elongation of the web, the winding tension must be controlled.

Web tension control then, is necessary to improve and ensure the flow of material during machine speed changes or to compensate for directional variations of the web as it is being wound. Web tension control methods vary significantly, from basically eye-balling the tension and manually making adjustments, to advanced tension sensing rollers and tension indicators that can automatically measure and make necessary adjustments during the process.

How Web Tension is Defined?

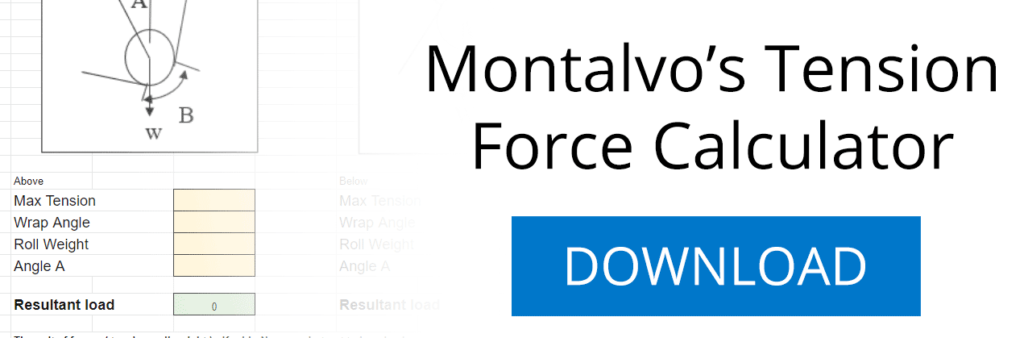

How web tension is defined and measured, is by the force per unit width, or simply, the unit tension of the material. This is largely determined by the thickness, the type of material being processed, and to some extent, the process itself. Units are generally measured in either the imperial system of measurement in terms of pounds per linear inch (PLI), or in the metric system of measurement, kilograms per centimeter (Kg/cm), or as Newtons per centimeter (N/cm). Another good example is the paper industry, which favors a method where unit tension is measured by the unit weight of the paper in terms of lbs. per 3,000 sq. ft. or grams per square meter.

Better Productivity with Web Tension Control

Finally, the correct winding tension and web tension controls relate directly to production efficiency. When winding reels, the degrees of tension must be controlled to exclude air from between the layers of material. Air entrainment can cause the roll to telescope, with layers sliding in and out of the reel. Too much tension between the layers may reduce air entrapment, but cause too much elongation and/or deformation of the material or, the elasticity of the material may cause the material to try and return to its original form, distorting the finished roll. In all cases, without correct web tension control the roll may be either be too soft from lack of proper tension control, or the roll core could be damaged or the roll telescoped because of high tension.

Finally, the correct winding tension and web tension controls relate directly to production efficiency. When winding reels, the degrees of tension must be controlled to exclude air from between the layers of material. Air entrainment can cause the roll to telescope, with layers sliding in and out of the reel. Too much tension between the layers may reduce air entrapment, but cause too much elongation and/or deformation of the material or, the elasticity of the material may cause the material to try and return to its original form, distorting the finished roll. In all cases, without correct web tension control the roll may be either be too soft from lack of proper tension control, or the roll core could be damaged or the roll telescoped because of high tension.

Winding tension and web tension control ensures product quality and production efficiency during the manufacturing process. The correct winding tension and proper tension control allow the web material to continuously pull at efficient speeds effectively. For manufacturers, in terms of productivity, correct tension is a must for both the material and the process.